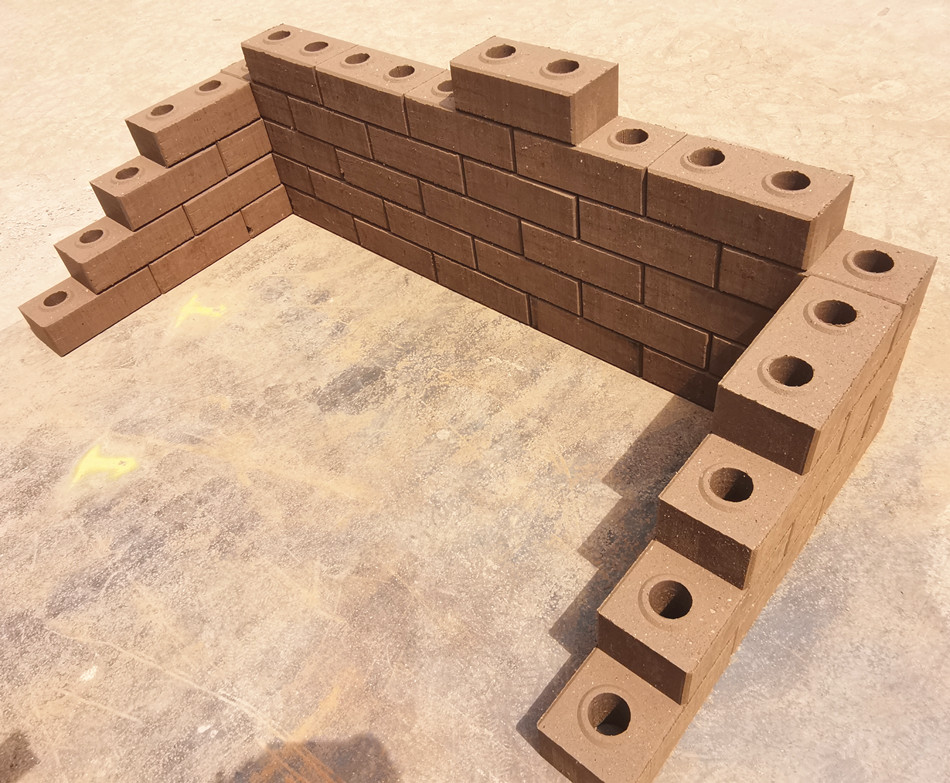

Introduction of SYN5-5 automatic clay issbs block production line with 100 tons pressure:

| Item No. | Name | Function |

| A | Soil Crusher (10-15 tons per hour) | Broken stones, clay blocks, get fine clay |

| B D | 4m Belt Conveyor (3pcs, one not show in photo) | Transfer materials to machine |

| C | Automatic Sieve | Take out stones and big size clay, get fine materials |

| E | Mixer (Diameter 1.5m, one bag 50KG cement) | Mixing clay with cement or other materials, include water |

| F | 6m Conveyor | Delivery mixed material to block machine material hopper |

| G | SYN5-5 block machine | Press blocks with 50 tons pressure |

| M | Air compressior | Supply power for block machine airbag clamp |

| S | Air spray handle | Spray air, take out more material on brick surface |

| H | Automatic control box | Control block machine work automatically |

| N | Block receiver | Delivery out fresh bricks out of block machine |

| Stacker (two types for optional) | Stack fresh blocks automatically |

Technical Information of SYN5-5 Automatic subsoil interlocking eco block machine:

| Model No. | SYN5-5 100Tons |

| Forming Cycle | 8-10 Second |

| Pressure of brick press cylinder | 100 tons (Head mold press oil cylinder perimeter 87cm) |

| With faster cylinder or not |

With faster design (small hydraulic oil tank on top, produce bricks faster) |

| Brick carry out method | Airbag clamp brick out, not harm brick bottom compare with old design |

| Raw material | Clay, subsoil, cement,fine stone powder… |

| Total Power of host machine | 16.85KW (Hydraulic Station motor 15kw) |

| Workers | 3-5 workers |

| Workshop Size (Min.) | 13m Length, 5m Width, 4m Height |

| Block Machine Size | 2750mm(L)-1950mm(W)-2750mm(H) |

| Host Block Machine Weight | 3600 KGS |

| JQ500 Mixer Capacity |

500L (One bag 50kg cement mixing a time) |

| Brick forming type | 100 tons pressure compressed clay forming bricks |

Production Capacity of SYN5-5 hydraulic automatic soil lego block machine:

GiantLin SYN5-5 automatic earth compressed block machine has different production capacity for different sizes of blocks, paver.

The following production capacities are for some popular sizes of blocks, bricks, hourdis and interlocking pavers.

| Item No. | Block Size | Production Capacity | Block Photo |

| 1 | Full brick

300-150-100mm |

5 blocks in a mold

1800 blocks per hour; 14400 blocks per 8 hours |

|

| 2 | Full brick

250-125-75mm |

5 blocks in a mold

1800 blocks per hour; 14400 blocks per 8 hours |

|

| 3 | U channel brick

250-125-75mm 300-150-100mm |

5 blocks in a mold

1800 blocks per hour; 14400 blocks per 8 hours |

|

| 4 | Half brick

125-125-75mm 150-150-100mm |

10 blocks in a mold

3600 blocks per hour; 28800 blocks per 8 hours |

|

| 5 | Solid interlock block

230-220-115mm |

3 blocks in a mold

1080 blocks per hour; 8640 blocks per 8 hours |

|

| 6 | Solid interlock brick

230-180-115mm |

4 blocks in a mold

1440 blocks per hour; 11520 blocks per 8 hours |

|

| 7 | Paving brick

200-100-80mm |

5 blocks in a mold

1800 blocks per hour; 14400 blocks per 8 hours |

|

| 8 | Zig Zag Paver

225-112.5-80mm |

5 blocks in a mold

1800 blocks per hour; 14400 blocks per 8 hours |

|

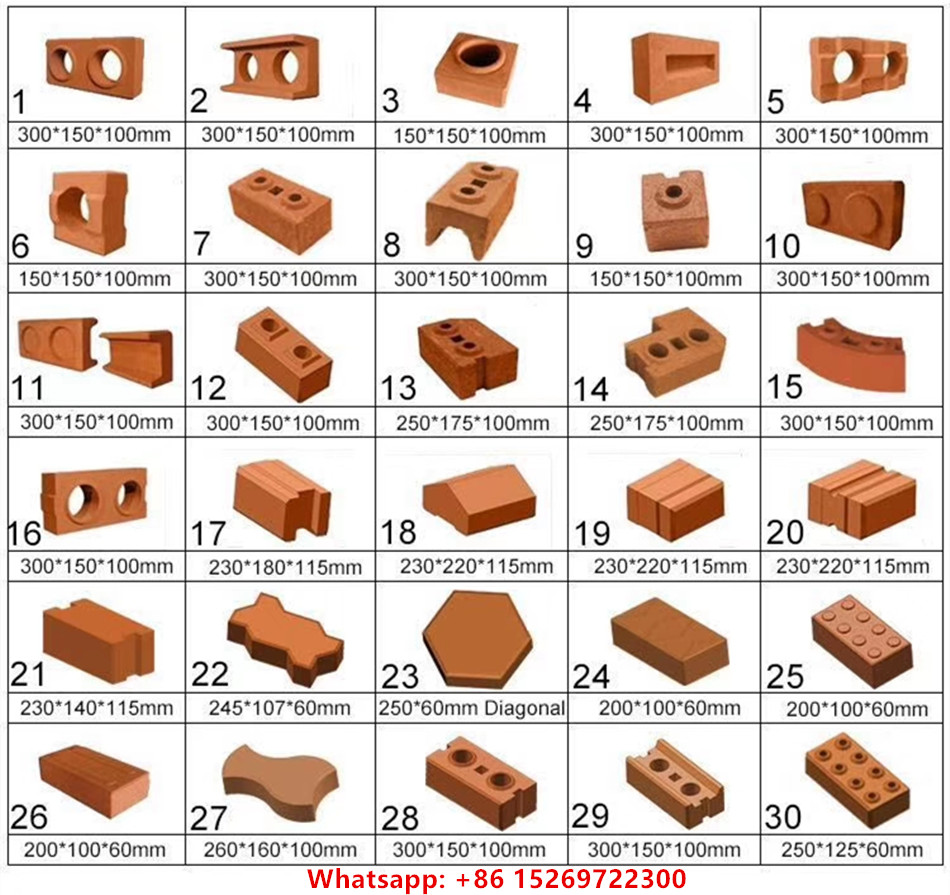

Design of lego blocks, paving bricksfor reference:

Clay brick samples(we could also produce patterned soil interlock bricks and decorative blocks)